如果您的组织计划利用物联网(IOT)以收集产品和系统的数据,请参阅货物在现场表演,增强工厂生产,或任何其他原因,需要熟悉概念“数字双胞胎。”

数字双胞胎是一种物理资产,过程或系统的数字复制品,可用于各种目的。对象的数字表示提供了对象在整个生命周期中运行的元素和动态。

数字双胞胎旨在是传感器数据可用的物理对象的所有元素的最新和准确的副本。数字双胞胎集成了人工智能,机器学习,预测分析和传感器遥测的技术,以创建物理机器的现场和历史表现的数字克隆,以及基于从现实世界实例收集的数据发展的理想化数字仿真模型。

The more highly instrumented a device is, the more accurately its digital twin will represent its actual historical performance, leading to better analysis and simulation of its future performance.

巨大影响

数字双胞胎有多少影响?该公司表示,研究公司Gartner Inc.将数字Twin命名为其前十大战略技术趋势。在三到五年内,数十亿的东西将由数字双胞胎代表数字双胞胎。

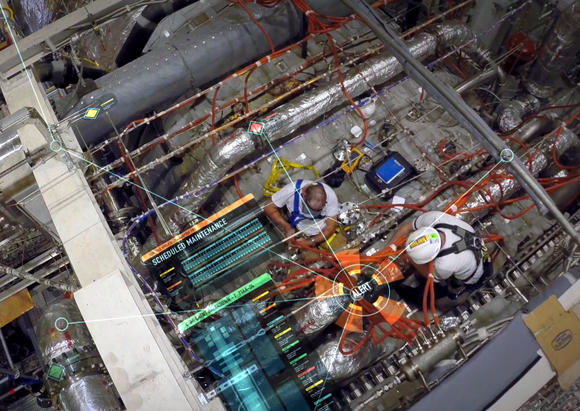

“Digital twins function as proxies for the combination of skilled individuals [for example, technicians] and traditional monitoring devices and controls” such as pressure gauges, Gartner says. They add value to traditional analytical approaches by enhancing situational awareness, and enabling better predictive responses to changing conditions. Digital twins can reduce operating expenses and potentially capital expenses, by extending the life of products or assets they represent and optimizing their performance.

Gartner表示,数字双胞胎的扩散将需要文化变革,因为那些了解与数据科学家和IT专业人士合作的现实世界的维护。“物理资产的数字双胞胎相结合的设施和环境的数字代表以及人们,企业和流程将使现实世界的仿真,分析和控制越来越详细的数字表示,”它说。

创新是必要的

Gartner提供有关如何在某种机构战略中开始使用数字双胞胎的一些建议,包括在IT领导和业务部门高管之间讨论有关数字双胞胎的潜在商业价值的讨论;以及如何解决增加不必要的复杂性,处理安全性和隐私等风险,

数字双胞胎不仅仅是一个“很好的”技术。根据研究公司国际数据公司(IDC),他们将是创新转型所必需的。基本上,数字双胞胎是仿真和可视化的扩展应用,在整个数字转换的组织中,为了更好的沟通和协作,坚定不移。

Digital twins are being used today in a variety of industries, including manufacturing, energy, transportation and construction. The types of products and facilities involved in digital-twin applications include aircraft engines, locomotives, offshore platforms, and wind turbines. Companies in these sectors are leveraging digital twins to optimize the operation and maintenance of these products.

这只是一个小的抽样。使用数字双胞胎的可能性看似无限。考虑到他们为公司提供了更好地了解产品性能的潜力,改善客户服务,提高业务和战略决策,不应该令人惊讶的是,高管热衷于了解如何最好地雇用这种令人兴奋的新技术。

三个关键领域

Digital twins can provide exceptional value for enterprises in three main areas. The first is in driving improvements in the manufacturing process. Companies can use digital twins throughout the manufacturing phases—from initial design to completed product—to make sure the observed performance of the manufactured product conforms to the design goals. Manufacturing operations can also be optimized by efficiently predicting production line failures and fixing them before they effect target production goals.

Another area is providing efficient predictive maintenance for existing products in the field. Digital twins can provide both historical and real-time data that technicians can leverage. Predictive algorithms can provide insight into potential failures before they occur. Technicians can use the the digital twin to make remote preventative adjustments, without having to go into the field to fix the physical product. When a physical fix is required, technicians can remotely diagnose the root cause of the problem and order the necessary parts before visiting the site to perform the repair.

第三个领域正在基于现实产品的现实世界的新产品开发新产品。在这里,数字双胞胎可以深入了解客户的使用方式以及如何在新产品设计和制造中进行更改,以提高市场渗透率和客户满意度。

很容易看出数字双胞胎如何对产品设计,制造和维护的方式产生巨大影响。公司可以获得销售福利,如降低成本,提高客户服务和新的收入机会。

As better sensors, networks, and analytics platforms are introduced with the ongoing growth of IoT, digital twins will become more and more of a reality for companies. By gathering and analyzing the data that is generated by twins, enterprises can truly reap the benefits of IoT.